Extracting Full Value From Data

This is an interesting article about big data in the manufacturing space.

Five guiding principles can help equipment OEMs and industrial equipment users to design a successful data-driven maintenance transformation that extracts full value from the data their equipment generates, argues Adrian Bostock.

Today’s industrial environment is a warehouse of data, with many pieces of equipment cranking out vast amounts of information about the way they have been working thanks to a growing suite of sensors and infrastructure that captures and collects data.

Most companies do a good job of collecting this data to figure out what happened, but then what? Many original equipment manufacturers (OEMs) are incorporating data capture and collection capabilities in their equipment and others are complementing this architecture with data repositories and advanced analytics layers.

Despite the access to these data, to extract full value from them – in particular reducing Total Cost of Ownership (TCO) and the impact of unplanned downtime – big steps still need to be made. Similarly, among their industrial customers there is a wide range of end users.

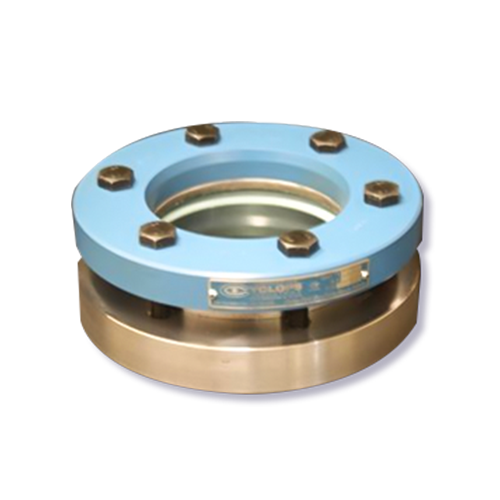

PRODUCT CATEGORIES

COMPANY

CERTIFIED SMALL BUSINESS

100% Women Owned Business

CAGE Code - ONDHO

NAICS Code - 327215

DUNS # 00501-7652

FM approved units

Units Registered in the US and in Canada

CONTACT INFORMATION

Cyclops Industries, Inc.

Mail: P.O. Box 8614 South Charleston, WV 25303

Office: 432 3rd Ave, South Charleston, WV, 25303, United States

Toll Free: 1-800-292-9011

Phone: (304) 744-9486

Fax: (304) 744-2505

© Copyright 2021-2025. Cyclops Industries, Inc. Designed and Maintained by Curio Creative Agency.