What are Sight Glasses?

And Why are They So Important

Sight glasses are a type of window or transparent panel installed in a piping system or vessel that allows the user to visually inspect the flow or contents of the system. They are commonly used in manufacturing plants to monitor the flow or level of liquids or gases in the system, and to ensure that the process is operating efficiently and safely.

There are several benefits to using sight glasses in a manufacturing plant:

Monitoring flow and level: Sight glasses allow operators to easily monitor the flow and level of liquids or gases in the system, which can be useful for identifying blockages, leaks, or other issues that may disrupt the manufacturing process.

Detecting changes in the process: Sight glasses can also help operators detect changes in the color, clarity, or other characteristics of the liquid or gas flowing through the system, which can be an indication of a problem or malfunction in the process.

Enhancing safety: By allowing operators to visually inspect the contents of a piping system or vessel, sight glasses can help prevent accidents or injuries caused by overfilling, leaks, or other hazards.

Improving efficiency: By enabling operators to quickly and easily identify and resolve issues in the manufacturing process, sight glasses can help improve the efficiency and productivity of the plant.

Overall, sight glasses are an important tool for maintaining and improving the safety, efficiency, and effectiveness of a manufacturing plant.

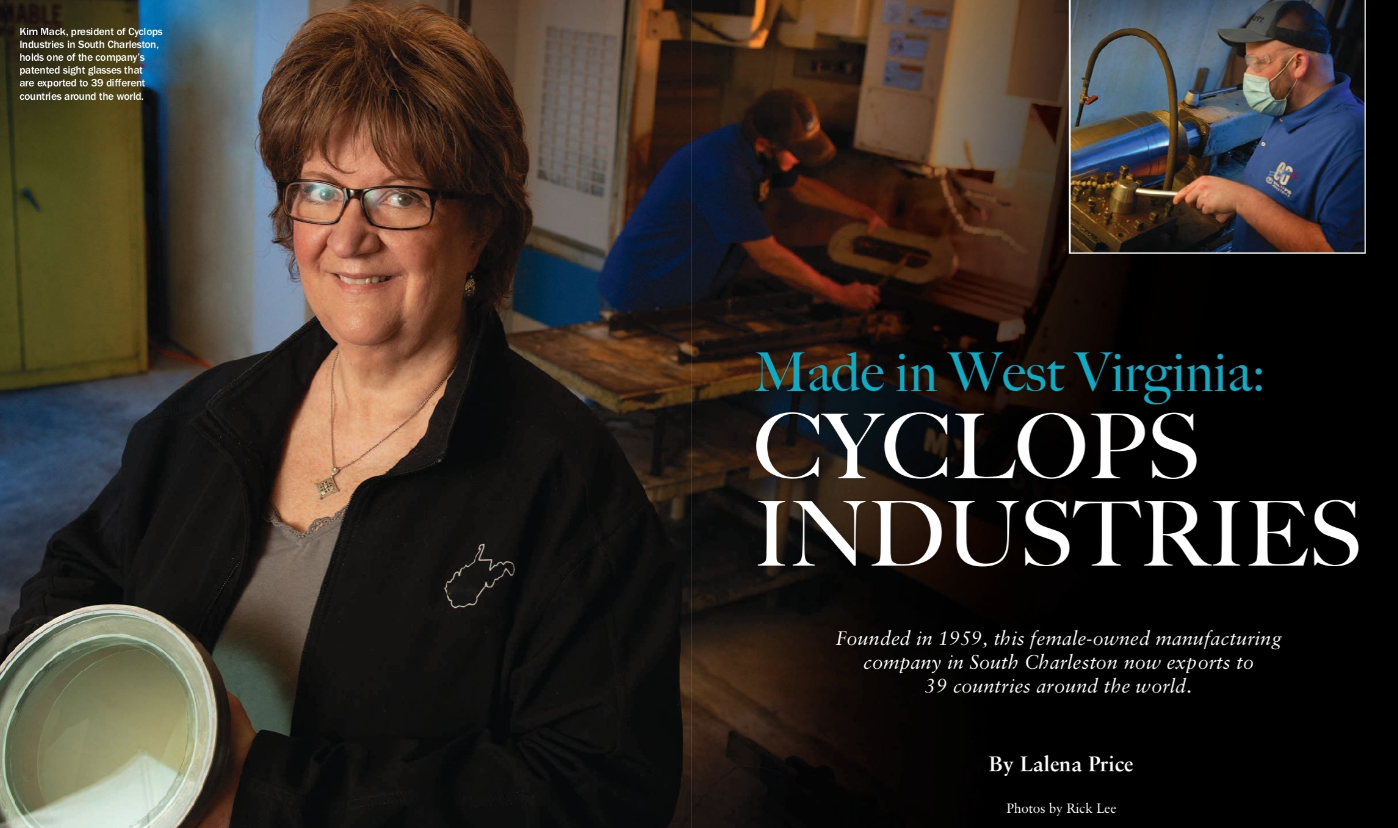

We have been manufacturing these for 64 years. And we ship to 37 different countries. We know this business!

Call us to learn more or place your order.

800-292-9011.