RCBI Assists Cyclops Industries in Achieving International Quality Certification

Cyclops Industries Receives ISO 9001:2015 Certification

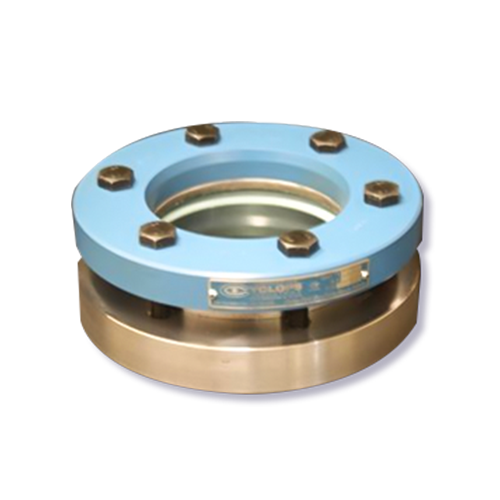

Cyclops Industries of South Charleston has been manufacturing quality for 63 years. The family-owned business’s industrial sight glasses provide a window through which processes that are under extremely high temperatures and/or high pressure can be monitored safely.

The patented devices are sold across the country and exported to customers in 39 countries around the world, with Chile just recently joining the growing league of nations. They’re found along pipelines, at chemical facilities, in industrial plants, even on the U.S. military’s fleet of nuclear submarines.

Manufactured to avert catastrophic failures, the sight glasses were developed by Cyclops President Kim Mack’s grandfather, a former Union Carbide employee who witnessed sight glass blowouts that not only led to costly material loss, but employee injuries caused by flying glass, spewing chemicals and scalding liquids.

“Though he wasn’t formally trained, my grandfather was an engineer in all respects,” Mack said. “He patented what we call the three-piece system. We base all of the pressure on the first piece of glass, so if something happens that the first piece of glass would ever fail, there are two behind them to keep people safe.”

Cyclops products have not only withstood pressure, but the test of time. Their quality keeps customers coming back. “When you give them good service, the product sells itself,” Mack said. “We’ve been doing it for 60-some years.”

Still, Mack decided in 2021 to pursue the official seal of quality for manufacturers: ISO 9001: 2015 certification, an international standard often required to export products, pursue government contracts – particularly military – or become a supplier to major primes (think DuPont, Northrop Grumman, etc.).

“Having ISO certification is a biggie in the manufacturing industry,” Mack said. “It lets customers and potential customers know that you’re consistently producing quality products.” ISO 9001 also involves a process of continual improvement to boost efficiency, reduce errors and maintain high standards of service.

Mack turned to Marshall University’s Robert C. Byrd Institute (RCBI) for assistance. Over the years, Cyclops had taken advantage of multiple RCBI services, including customized training in CNC mill operation and workforce development through Apprenticeship Works, RCBI’s National Advanced Manufacturing Apprenticeship Partnership.

RCBI was able to cover the cost of its services under a grant from the AIM Higher Consortium, a southwestern Pennsylvania and West Virginia collaborative (of which RCBI is a partner) to connect manufacturers to the military supply chain. One way it does that is by assisting companies such as Cyclops in achieving the certifications they need to bid on military contracts.

Members of RCBI’s Quality Implementation team, Erica Cheetham and Carmen Archer, traveled to Cyclops’s manufacturing facility and worked closely with Mack and her crew for several months to prepare for the audit that ultimately led to certification. This involved documenting work procedures of each employee and developing and implementing a formal written Quality Management System that includes procedures for corrective actions if problems arise.

With RCBI’s assistance, Cyclops passed the certification audit earlier this year – on the first try. Now, said Mack, the company has a formal system in place to preserve the knowledge of seasoned employees and pass it on to new hires, ensure consistent quality of products and services as well as qualify the company to pursue new opportunities.

Mack said preparing for the ISO 9001 certification audit was a lengthy process because of the detail and precise documentation required, but it was worth the time.

“ISO 9001 lets the world know that we produce a quality product, that we follow the same system each time and that we care about how we make our products,” she explained. “Without Erica and Carmen, we never would have been able to do it.”

RCBI has assisted dozens of West Virginia companies in achieving first-time ISO certification. For more information about its full line of Quality Implementation assistance, visit www.rcbi.org/quality or contact Cheetham at echeetham@rcbi.org or 304.781.1687.

To learn more about Cyclops Industries, the 2021 West Virginia Family-Owned Small Business of the Year as designated by the District Office of the U.S. Small Business Administration, visit www.cyclopswv.com.

Or call us at 800-292-9011.