Supply Chain Expo to Connect State Suppliers

Annual event connects suppliers to manufacturers

The Robert C. Byrd Institute (RCBI) and Advantage Valley will sponsor a free online expo August 10 to link small-scale suppliers of goods and services to Chemours, a major state manufacturer of chemicals and related products.

Participants in the Chemours Supply Chain Expo will learn about the processes to become suppliers and how to bid on contracts. Officials with Chemours’s Belle plant are interested in connecting to suppliers of a variety of goods and services, including:

- Maintenance parts/supplies (motors, wires, electrical components, gaskets, O-rings, couplings, lubrication, manual valves, studs / fasteners, etc.)

- Pipe fabrication

- Machining

- Packaging materials such as drums and totes

- Office furniture

- Banners/flags/signs with company branding

- Food Service – run the site cafeteria or food trucks, etc.

- Weed control

- Pest control

- Pressure relief valve test / Repair

- Coatings / insulation

- Asbestos / lead abatement

- Electric motor test / repair

- Pump repair

- Large electrical transformer testing / maintenance

- Heat exchanger repair / eddy current testing

- Roofing repairs (particularly flat rubber roofs)

- Construction services (civil, piping, scaffolding)

- HVAC repairs / service

The Aug. 10 virtual Supply Chain Expo will run from 2 p.m. to 3:30 p.m. The event is free but registration is required below. For more information, contact RCBI’s Derek Scarbro at 304.781.1684 or Advantage Valley’s Terrell Ellis at 304.546.7323.

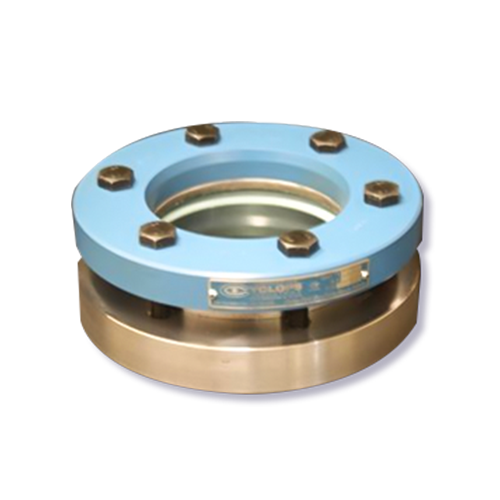

PRODUCT CATEGORIES

COMPANY

CERTIFIED SMALL BUSINESS

100% Women Owned Business

CAGE Code - ONDHO

NAICS Code - 327215

DUNS # 00501-7652

FM approved units

Units Registered in the US and in Canada

CONTACT INFORMATION

Cyclops Industries, Inc.

Mail: P.O. Box 8614 South Charleston, WV 25303

Office: 432 3rd Ave, South Charleston, WV, 25303, United States

Toll Free: 1-800-292-9011

Phone: (304) 744-9486

Fax: (304) 744-2505

© Copyright 2021-2025. Cyclops Industries, Inc. Designed and Maintained by Curio Creative Agency.